Our Commitment to

The Caribbean

Caribbean Water Solutions: Dedicated To Building Island Infrastructure

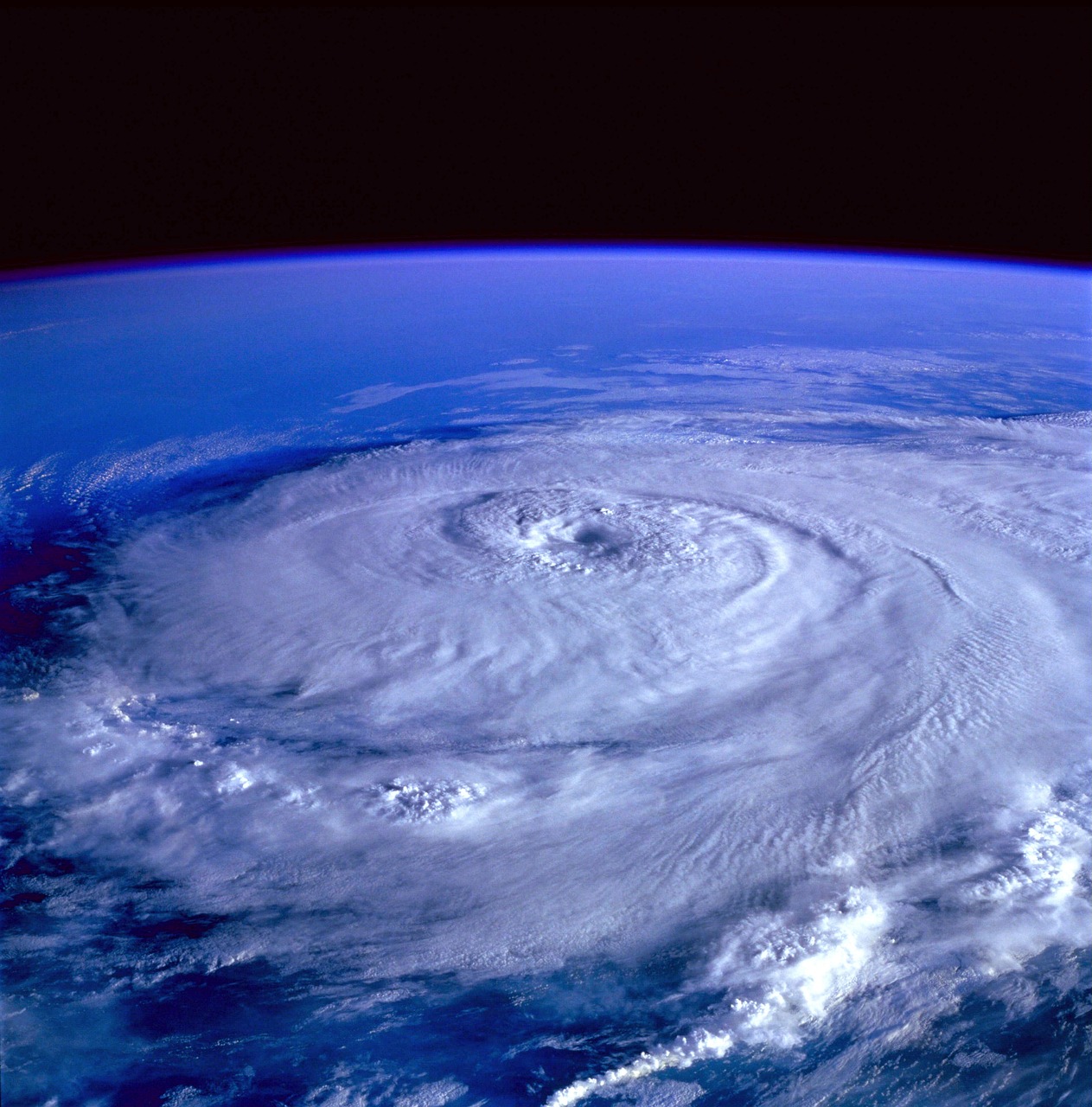

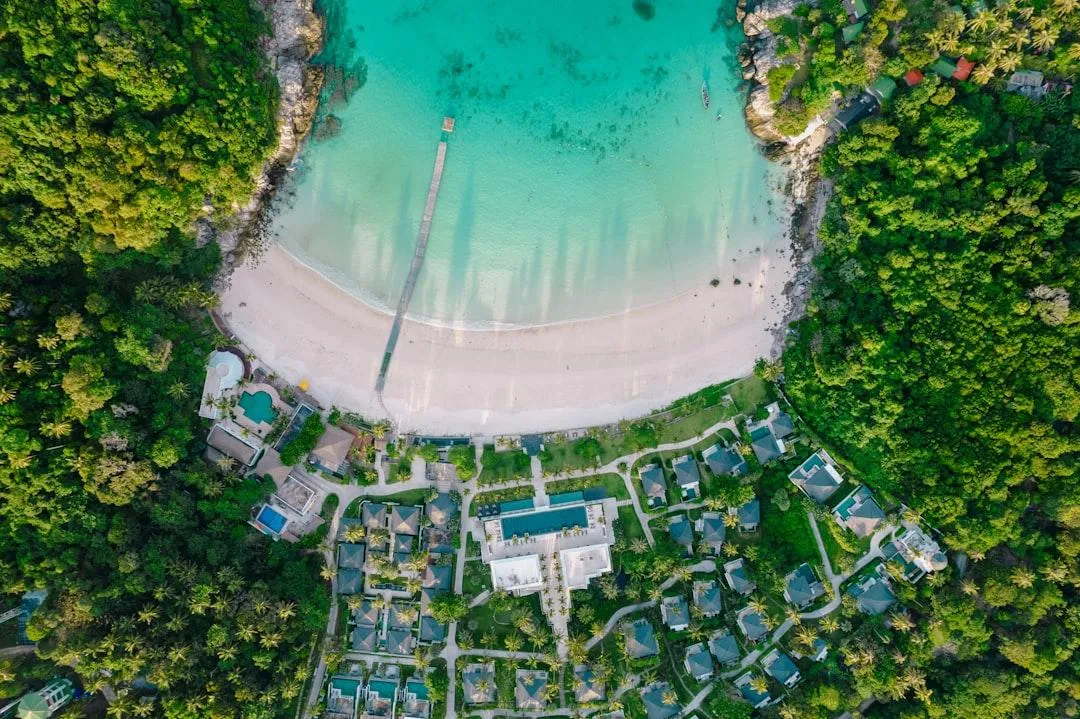

Caribbean islands face water challenges that demand specialized solutions—limited freshwater, aging infrastructure, hurricane vulnerability, and tourism-driven demands. Carver Water Technology delivers field-proven systems designed for island conditions, backed by strategic partnerships with industry leaders.

From containerized water systems deployed after Hurricanes, to compact wastewater systems for resort communities, we bring technology that works in the Caribbean's toughest conditions.

Water Treatment

Solutions

Expert Contaminant Removal In The US and The Caribbean

When water quality threatens operations, compliance, or safety, Carver Water Technology delivers proven solutions. From municipal utilities to industrial facilities, we've built our reputation on eliminating contaminants that disrupt business, damage equipment, and violate drinking water standards.

Based in Tampa with coverage across the Southeastern United States and the Caribbean, our team of water treatment professionals responds to your water challenges with the same urgency you face—because we know that in your business, water problems don't wait.

The Caribbean Water Challenge

Island water systems operate under constraints that mainland utilities never face. Understanding these challenges is the first step toward reliable solutions.

Limited Freshwater Resources

Most Caribbean islands lack sufficient freshwater aquifers. Groundwater resources are limited, vulnerable to saltwater intrusion, and often brackish. Surface water is scarce outside of rainy seasons. Traditional water sources that serve continental communities simply don't exist at the scale Caribbean populations require.

The Impact: Communities depend on expensive desalination, water imports, or unreliable rainfall catchment. During drought years, water scarcity threatens economic activity, particularly tourism—the economic engine for most Caribbean nations.

Aging Infrastructure and Water Loss

Many Caribbean water distribution systems were installed decades ago and suffer from chronic leakage. Non-revenue water (NRW), the difference between water produced and water billed, commonly exceeds 40-60% across the region. Some systems lose more water to leaks than they deliver to customers.

The Cost: Governments pay to produce, treat, and pump water that never generates revenue. Energy costs for pumping leaked water drain utility budgets. Customers face water shortages while treated water pours into the ground from corroded pipes.

Tourism-Driven Demand Surges

Caribbean economies depend on tourism. Hotels, resorts, and cruise ship passengers create dramatic seasonal water demand fluctuations. A 400-room resort uses as much water as a small town, all concentrated in a few acres.

The Challenge: Water systems must handle peak tourist season demands while remaining economically viable during low season. Resorts in remote locations often operate independent water systems because municipal infrastructure can't serve them reliably.

Hurricane and Disaster Vulnerability

Atlantic hurricane season brings existential threats to Caribbean water infrastructure. Category 4 and 5 hurricanes destroy treatment plants, contaminate wells, and shatter distribution systems. Recent storms like Dorian in the Bahamas, Maria in Puerto Rico, Irma across the Eastern Caribbean, left communities without water for months.

The Reality: Caribbean water systems must be designed for rapid restoration after disasters. Backup systems, mobile treatment units, and emergency response capabilities aren't luxuries, they're requirements for island communities.

Energy Costs and Grid Reliability

Caribbean electricity costs rank among the world's highest, often 3-5 times continental US rates. Water treatment is energy-intensive. Pumping, desalination, and treatment drive operational costs that make water service expensive and sometimes unaffordable.

Grid reliability issues compound the problem. Power outages shut down treatment plants and pumping stations, disrupting water service even when systems are otherwise functional.

Caribbean Water Solutions: What We Provide

Containerized Mobile Water Treatment:

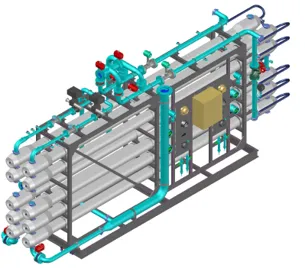

Rapid Deployment RO Systems

Water emergencies, resort expansions, and seasonal demands require treatment capacity that deploys in weeks, not years. Our containerized reverse osmosis systems arrive ready to operate! Just connect power, a water source, and hook up the distribution piping.

Mobile RO System Portfolio

Brackish Water RO (BWRO) - Containerized Units:

Treat groundwater with TDS ranging from 2,000-10,000 mg/L, producing drinking water quality at 1/3 the energy cost of seawater desalination.

Small Scale: ~10-15 GPM production (14,400-21,600 GPD)

Medium Scale: ~20-35 GPM production (28,800-50,400 GPD)

Large Scale: Custom configurations for higher flows

Seawater RO (SWRO) - Containerized Units:

Convert ocean water into potable supply for coastal communities and island resorts without freshwater access.

Production rates customized to project requirements

High-efficiency energy recovery devices minimize operating costs

Corrosion-resistant materials survive marine environments

System Features & Capabilities

Rapid Deployment: Delivery in 2-8 weeks depending on configuration. All units ship in standard 40-foot ISO containers and are transportable by truck, rail, or vessel to any Caribbean island.

Plug-and-Play Operation: Systems arrive fully assembled, piped, wired, and tested. Installation requires only:

Power connection (grid or generator)

Raw water intake connection

Treated water discharge piping

Basic site preparation

Remote Monitoring: HMI interfaces with remote SCADA access provide real-time system diagnostics, performance data, and water quality tracking,allowing troubleshooting from our Florida headquarters even for remote island installations.

Flexible Leasing: Monthly, quarterly, or annual lease terms available. No massive capital investment required—operational expense budgeting makes projects financially feasible.

Support Packages: Startup assistance, operator training, and preventive maintenance programs available. We don't deploy systems and disappear, our ongoing support ensures reliable operation.

Caribbean Mobile RO Applications

Emergency & Disaster Response: Hurricane damage to municipal systems creates immediate water crises. Mobile RO units restore supply within days while permanent repairs proceed over months.

Resort Water Supply: Independent systems ensure guest experience quality regardless of municipal service reliability. Seasonal capacity additions handle peak occupancy without permanent infrastructure investment.

Municipal Pilot Projects: Test desalination viability before committing to permanent facilities. Gather operational data, refine designs, and demonstrate technology to stakeholders.

Industrial Expansion: Temporary treatment during facility expansions or process changes. Add capacity quickly without disrupting ongoing operations.

Construction Projects: Provide potable water for major construction sites in remote locations. Remove when project completes—no permanent infrastructure required.

Carver Water Technology has designed and maintained RO systems for challenging applications across Florida and the Caribbean region. Our engineering team understands the specific demands of island desalination,from intake design through brine disposal.

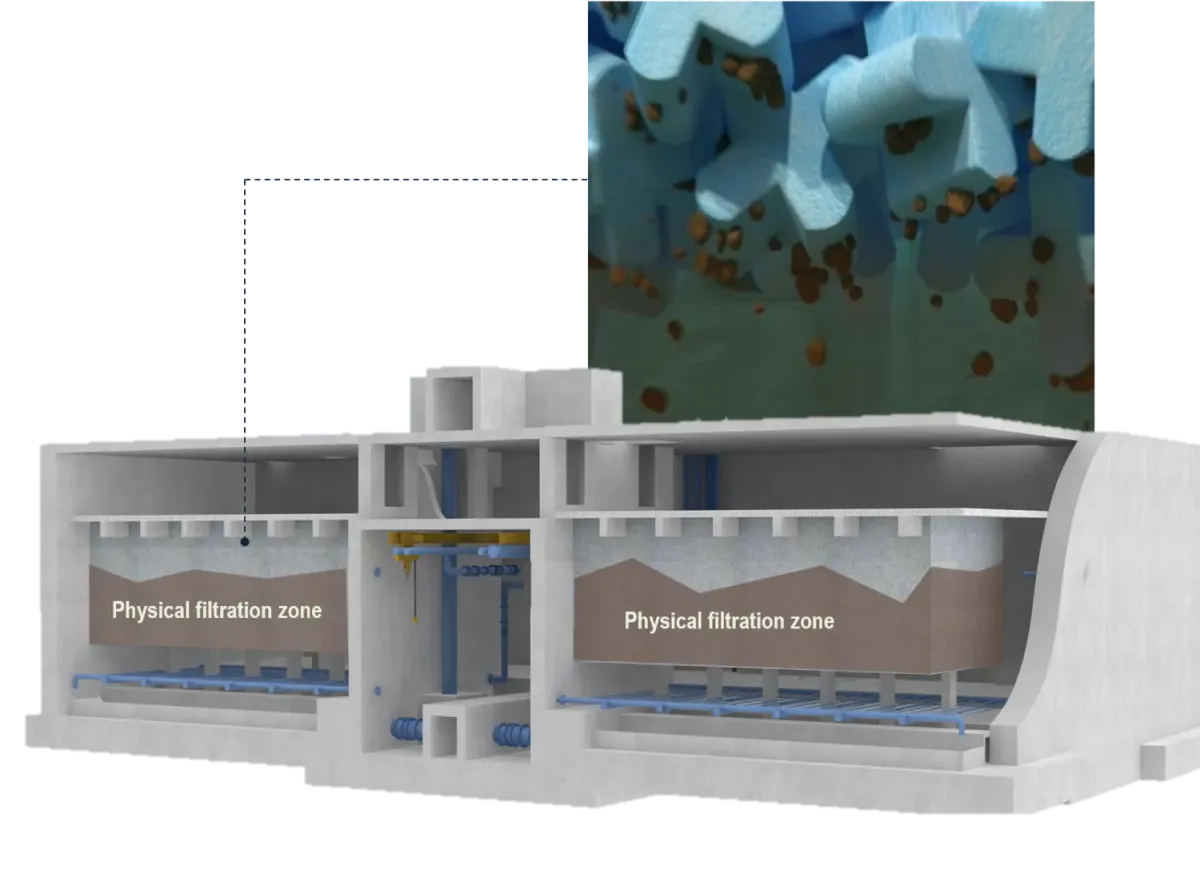

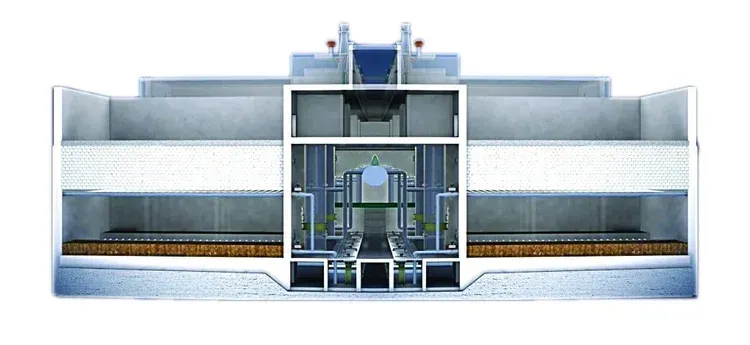

Proteus Wastewater Treatment: Compact Systems for Space-Constrained Islands

Caribbean resorts and communities face a challenge: growing wastewater treatment needs with limited available land. Traditional treatment plants require acres. Island properties often have only square feet.

Proteus technology solves this through ultra-compact biological filtration that treats wastewater in 80% less space than conventional systems.

Proteus Technology Overview

Developed by Tomorrow Water and deployed by Carver Water Technology, Proteus represents advanced primary and biological treatment combined into single reactors.

How Proteus Works:

High-speed upflow filtration with buoyant media captures suspended solids and organics in just 15 minutes, using only 20% of the space required by conventional clarifiers and aeration basins.

Proteus Plus configuration adds aerated biofilm layers for complete secondary treatment (BOD reduction, nitrification, and denitrification) within the same compact footprint.

Performance Specifications

Solids Removal: Up to 80% TSS removal in primary configuration

Organic Removal: Up to 90% BOD reduction in Proteus Plus configuration

Nutrient Removal: Nitrification and denitrification in single reactor (Proteus NDN configuration)

Footprint Reduction: 80-85% smaller than conventional treatment systems

Treatment Time: 15 minutes primary treatment vs. 4-8 hours conventional

Energy Efficiency: 35-45% oxygen transfer efficiency vs. 15-25% conventional systems—reducing largest operating cost in biological treatment

Caribbean Applications for Proteus

Resort & Hotel Wastewater:

Caribbean resorts generate wastewater flows equivalent to small municipalities, but on properties with limited available land and aesthetic constraints that make traditional treatment plants unacceptable.

Proteus systems fit in mechanical rooms, landscaped areas, or small parcels that would never accommodate conventional plants. Treated effluent can be reused for irrigation, cooling towers, and non-potable applications, reducing freshwater demand.

Community Wastewater Treatment:

Small island communities need treatment plants but lack land for sprawling conventional facilities. Proteus provides municipal-quality treatment in compact installations suitable for space-constrained coastal towns.

Mixed-Use Developments:

New developments on Caribbean islands must provide their own infrastructure. Proteus allows developers to include wastewater treatment without dedicating valuable land that could generate revenue through resort, residential, or commercial use.

Existing Plant Upgrades:

Retrofit existing conventional plants to increase capacity, improve effluent quality, or add nutrient removal, without expanding facility footprint. Perfect for communities facing new regulations or population growth with no room to expand treatment plants.

Wet Weather Flow Management:

Handle peak flows during tropical storms without massive storage tanks or overflow events. Proteus manages high peaking factors and variable flow rates that challenge conventional systems.

Why Proteus Fits Caribbean Conditions

Land is expensive: Island property values make compact treatment economically essential

Hurricane resilience: Low-profile systems with minimal above-ground infrastructure survive storms better than conventional plants with large clarifiers and aeration basins

Energy costs: Caribbean electricity rates (3-5x US mainland) make Proteus' energy efficiency critical for affordable operation

Reuse requirements: Drought-prone islands increasingly require wastewater reuse. Proteus produces high-quality effluent suitable for irrigation and industrial applications

Simple operation: Limited technical staff availability on islands demands systems that operate reliably with minimal operator intervention

Atmospheric Water Generation: Creating Water from Air

When freshwater doesn't exist, you create it. Our Atmospheric Water Generation (AWG) systems produce pure drinking water from humidity. No wells, no pipes, no ocean intake required.

Proven Caribbean Deployment: Hurricane Maria Response

Following Hurricane Maria's devastation of Puerto Rico in 2017, our AWG partner, the Moses West Foundation, deployed large-scale atmospheric water generators to Vieques, providing clean drinking water for 15,000 residents when traditional infrastructure lay in ruins. The system operated on solar power, producing thousands of gallons daily even in harsh conditions and variable electrical supply.

The Puerto Rico National Guard recognized this deployment as demonstrating "excellent atmospheric water generation" and "remarkable and enduring devotion to the citizens of the island that lacked this essential resource."

AWG Technology Specifications

AWG-800 Model:

Production: Up to 800 liters (211 gallons) per day

Energy: Low consumption at ~0.18 kWh/liter

Applications: Community centers, medical facilities, light industrial

Transport: Compact units, up to 16 units per 20' ISO container

Power: Grid, generator, or solar capability

AWG-5000 Model:

Production: Up to 8,400 liters (2,200 gallons) per day

Scalability: Multiple units create unlimited capacity facilities

Deployment: Fully containerized in 20-foot ISO containers

Military-grade: Ruggedized for field deployment

Power Options: Grid, diesel generator, natural gas, or renewable sources

Rapid Setup: One-button start, immediate water production

Caribbean AWG Applications

Disaster Relief & Hurricane Recovery: Immediate potable water when infrastructure fails. Proven performance in Puerto Rico's post-Maria conditions demonstrates reliability when communities need it most.

Remote Resorts & Hotels: Water independence for properties where municipal supply is unreliable or non-existent. Eliminates dependence on water trucks and ensures guest experience quality.

Out Island Communities: Sustainable water supply for Family Islands, remote settlements, and coastal communities with limited freshwater resources.

Government Facilities: Critical infrastructure including hospitals, emergency services, and administrative centers requiring reliable backup water supply.

Industrial & Agricultural: Supplemental water for operations in water-scarce regions where wells or municipal sources are limited or contaminated.

Why AWG Works in the Caribbean

High humidity environments maximize AWG production efficiency. Caribbean islands provide ideal conditions for atmospheric water generation, typically 60-85% humidity year-round. Water quality exceeds WHO and EPA standards without requiring treatment of contaminated source water.

Hurricane-resistant systems continue operating when conventional infrastructure fails, providing the resilience island communities require.

Additional Treatment Technologies

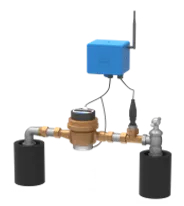

Water Loss Reduction & NRW Management

Non-revenue water commonly exceeds 40-60% across Caribbean utilities—treated water leaking from corroded pipes rather than generating revenue.

We provide:

Acoustic leak detection services

District metering area (DMA) implementation

Pressure management systems

GIS-based pipe rehabilitation planning

Smart metering and AMI deployment

Reducing NRW delivers more water without building new treatment capacity—often the highest-return investment available.

Desalination System Design & Engineering

Custom-engineered seawater and brackish water RO systems sized for your specific requirements:

Municipal water supply systems

Resort independent water systems

Industrial process water

Permanent installations with full O&M support

Filtration & Pretreatment Systems

Protect membrane systems and remove turbidity:

Multimedia filtration

Ultrafiltration/Microfiltration pretreatment

DAF (Dissolved Air Flotation) systems

Chemical dosing and conditioning

Disinfection Systems

Ensure microbiological safety:

UV disinfection systems

Chlorination feed systems

Ozone generation (where applicable)

Industry Specific Needs

Resort and Hospitality Water Systems

Caribbean resorts operate as self-contained communities, requiring reliable water supply and treatment regardless of municipal service availability. Guest satisfaction and brand reputation depend on water quality that meets international hospitality standards.

Resort Water Treatment Solutions:

Independent Water Supply: Desalination systems, well treatment, and storage that ensure water availability regardless of municipal supply reliability.

Water Softening: Protects laundry equipment, boilers, and guest fixtures from hard water damage. Softened water improves guest experience: softer towels, better-lathering soap, no mineral deposits on fixtures.

Filtration and Aesthetic Treatment: Removes color, taste, and odor issues that affect guest perception of water quality. Crystal-clear, great-tasting water is a hospitality expectation.

Pool and Spa Treatment: Specialized filtration and disinfection systems for pool and spa facilities serving hundreds of guests daily.

Water Reuse Systems: Treated wastewater reuse for irrigation, cooling towers, and non-potable applications reduces freshwater demand and operational costs.

Emergency Backup Systems: Redundant treatment capacity and storage ensure water service continues during equipment failures or natural disasters, protecting hotel operations and guest safety.

Why Resorts Choose Our Systems:

Reliability: Hotel and resort operations cannot tolerate water service interruptions. Our systems include redundancy and remote monitoring that ensure continuous operation.

Water Quality: International guests expect water quality matching their home countries. Our treatment systems meet WHO and EPA standards.

Operational Support: We provide operator training, preventive maintenance, and emergency service, ensuring your team can manage systems confidently.

Rapid Mobilization: When emergencies occur, we deploy from Florida within 24-48 hours, carrying critical spare parts and expertise to restore service quickly.

Emergency Response and Disaster Recovery

Hurricane season brings predictable devastation to Caribbean water infrastructure. Communities need partners who respond when disaster strikes, not months later when contracts are signed, but immediately when water service fails and public health is at risk.

Our Emergency Response Capabilities:

Mobile Treatment Units: Containerized RO systems, filtration units, and disinfection systems that deploy within 24-48 hours from our Florida facilities. Systems arrive ready to operate, requiring only power, water source connection, and distribution hookup.

Rapid Assessment Teams: Our engineers deploy to assess damage, identify critical needs, and design temporary solutions that restore service while permanent repairs proceed.

Temporary Water Distribution: Bulk water storage, distribution tankers, and point-of-distribution treatment stations provide safe water while infrastructure repairs progress.

Generator and Power Solutions: Our mobile systems operate on generators, allowing water production even when grid power remains offline for weeks.

Spare Parts and Consumables: We maintain inventory of critical components, membranes, pumps, filters, disinfection chemicals, that deploy with our emergency systems.

Post-Hurricane Response Protocol:

Within 24 Hours: Emergency assessment team mobilizes from Tampa, carrying satellite phones and assessment equipment.

Within 48 Hours: Mobile treatment units deploy via cargo flight or sea freight, depending on port and airport conditions.

Within 72 Hours: Temporary water production begins, serving priority facilities (hospitals, shelters, government operations).

Ongoing: We maintain emergency systems, provide operator training, and transition to permanent repairs as conditions allow.

Recent Caribbean Disaster Response:

Caribbean communities remember Hurricane Dorian's devastation across Abaco and Grand Bahama in 2019. When the next major hurricane strikes, the response time determines how quickly communities recover. Our Florida location positions us as the nearest qualified responder to most Caribbean islands.

Read Our Blog To Learn More About Our Us

Carver Water Technology Commissions Advanced MBBR Wastewater System in Runaway Bay, Jamaica

Carver Water Technology is bringing cutting-edge wastewater treatment to Jamaica's North Coast through a strategic partnership with Isratech Jamaica. This 300 m³/day MBBR (Moving Bed Biofilm Reactor) ... ...more

Waste Water Treatment Solutions ,Caribbean

December 17, 2025•13 min read

Serving Remote Communities: How Carver Water Technology Restored Critical Water Infrastructure to South Andros, Bahamas

The Rahming Store isn't just a business, it's a cornerstone of the community. Ensuring its water system operated flawlessly means preserving a cornerstone of South Andros life. Once the system arrive... ...more

Water System Repairs ,Reverse Osmosis & Deionization &Caribbean

December 17, 2025•18 min read

Current Caribbean Island Footprint

The Bahamas

Market Focus: Nassau/New Providence municipal infrastructure, Grand Bahama post-Hurricane Dorian recovery, Out Island resort development, Family Island community water supply

Technologies: AWG for remote islands, mobile RO for disaster recovery, Proteus for resort wastewater, desalination for coastal communities

Jamaica

Market Focus: Tourism sector water independence, municipal infrastructure support, industrial process water, agricultural water supply

Technologies: Resort wastewater treatment (Proteus), desalination for coastal properties, mobile RO for industrial applications, water loss reduction for utilities

Trinidad & Tobago

Market Focus: Industrial water treatment, oil & gas sector applications, municipal desalination, resort water systems

Technologies: Industrial RO systems, brackish water treatment, mobile treatment for industrial expansion, Proteus for space-constrained facilities

Future Island Coverage

Carver Water Technology strives to serve these islands int he future. Let's help implement further water infrastructure throughout the Caribbean region, together:

Lesser Antilles: Antigua & Barbuda, Dominica, Grenada, St. Kitts & Nevis, St. Lucia, St. Vincent & the Grenadines, Barbados

Greater Antilles: Dominican Republic, Haiti, Puerto Rico

Leeward/Windward Islands: Anguilla, Montserrat, British Virgin Islands, US Virgin Islands

Southern Caribbean: Aruba, Barbados, Bonaire, Curaçao, Guyana, Suriname

Each island presents unique water challenges. We customize solutions based on local conditions, available resources, and regulatory requirements.

We Provide Complete Project Lifecycle Support

From feasibility studies through decades of operational support:

Initial assessment and system design

Financing support and project development

Equipment procurement and logistics

Installation, commissioning, and startup

Operator training and technical transfer

Preventive maintenance and optimization

Emergency repair and spare parts support

Real World References

Technology Deep Dives:

Atmospheric Water Generation: Caribbean Applications (coming soon)

Proteus Wastewater Treatment: Resort & Community Systems (coming soon)

Mobile RO Systems: Emergency Response & Temporary Treatment (coming soon)

Caribbean Water Challenges:

Hurricane-Resilient Water Infrastructure Design (coming soon)

Water Loss Reduction in Caribbean Utilities (coming soon)

Desalination vs Alternative Technologies: Decision Framework (coming soon)

Project Development:

Caribbean Water Project Financing Guide (coming soon)

Public-Private Partnerships for Island Water Infrastructure (coming soon)

Frequently Asked Questions

Q1: What exactly are PFAS and why are they called “forever chemicals”?

PFAS (Per- and Polyfluoroalkyl Substances) are a class of over 4,700 synthetic fluorinated compounds. Their key feature is a fluorine-carbon (C–F) bond, one of the strongest in chemistry, which makes PFAS highly resistant to heat, chemical breakdown, and environmental degradation. This durability means PFAS persist indefinitely in water, soil, and living organisms—hence the name “forever chemicals.”

Q2: Which PFAS compounds are regulated under the new EPA rules?

In 2024, the EPA finalized Maximum Contaminant Levels (MCLs) for several PFAS:

PFOA and PFOS: Set at 4 parts per trillion (ppt) each.

GenX (HFPO-DA) and PFBS: Regulated individually at higher ppt thresholds.

PFNA and PFHxS: Addressed in a combined hazard index approach.

These levels are extremely low, reflecting the toxicity of PFAS even in trace concentrations.

Utilities must monitor and treat water to meet these limits.

Q3: How do PFAS typically enter drinking water systems?

PFAS contamination occurs through several pathways:

Industrial discharges from manufacturing plants.

Wastewater treatment plant effluent, which returns PFAS-laden water to rivers.

Firefighting foam (AFFF) runoff from military bases and airports.

Landfill leachate and biosolids applied to agricultural fields.

Atmospheric deposition from PFAS released through factory emissions.

Once PFAS reach surface water or groundwater, they spread widely and infiltrate municipal supplies.

Q4: Which PFAS treatment technologies are most effective?

There is no single “perfect” technology, but leading options include:

Granular Activated Carbon (GAC): Effective for long-chain PFAS like PFOA and PFOS, but less efficient for short-chain compounds such as GenX.

Ion Exchange (IX): Strong-base anion resins can remove both long- and short-chain PFAS, but resin fouling and PFAS-concentrated brine disposal remain challenges.

Reverse Osmosis (RO) and Nanofiltration (NF): RO provides comprehensive removal of nearly all PFAS, while NF is more energy-efficient but less effective on short-chain PFAS. Both generate brine waste streams requiring careful disposal.

Advanced Oxidation Processes (AOP) and Electrochemical Oxidation: These methods can potentially degrade PFAS at the molecular level, but they are energy-intensive and still emerging technologies.

Carver Water often engineers integrated systems (e.g., GAC + RO + IX polishing) to balance cost, efficiency, and waste management.

Q5: What happens to PFAS after treatment—are they destroyed?

This depends on the method:

Adsorptive methods (GAC, IX): PFAS are captured in the media, which then becomes hazardous waste requiring regeneration or high-temperature incineration.

Membrane methods (RO, NF): PFAS are concentrated into a brine waste stream, typically 15–25% of the treated water volume. Brine disposal (deep well injection, evaporation ponds) is costly and tightly regulated.

Destructive methods (AOP, Electrochemical): Aim to break down PFAS into less harmful byproducts. However, incomplete degradation can lead to toxic intermediates, and these technologies are still under optimization.

Q6: How big is the PFAS treatment market?

According to Bluefield Research, U.S. utilities will spend over $3 billion annually by 2030 on PFAS remediation technologies. Drivers include:

-Growing public health awareness.

-New state and federal mandates under the Safe Drinking Water Act.

-Federal grants funding PFAS technology pilots.

-Legal liabilities faced by manufacturers and utilities.

This makes PFAS the next major challenge for U.S. water utilities.

Q7: What are the biggest challenges with PFAS compliance?

Ultra-low regulatory limits (parts per trillion) require highly sensitive monitoring and treatment.

Short-chain PFAS removal remains technically difficult.

Disposal of PFAS waste (spent media, brine) is costly and environmentally sensitive.

High operational costs for advanced technologies like RO and AOP.

Uncertainty around future regulation—EPA is expected to expand its list of regulated PFAS compounds.

Carver Water’s role is to help utilities choose the right mix of technologies, secure funding, and manage ongoing compliance.

👉 Still have questions?

We're Here To Help!

PFAS isn’t going away—but your community doesn’t have to face it alone.

Let's remove PFAS together!

Innovation

Fresh, creative solutions.

Integrity

Honesty and transparency.

Excellence

Top-notch services.

FOLLOW US

TECHNOLOGY & SERVICES

ABOUT US

CUSTOMER CARE

LEGAL

Copyright 2026. Carver Water . All Rights Reserved.