DRACO

Thermal Hydrolysis

Engineering The End Of Sludge

What is DRACO?

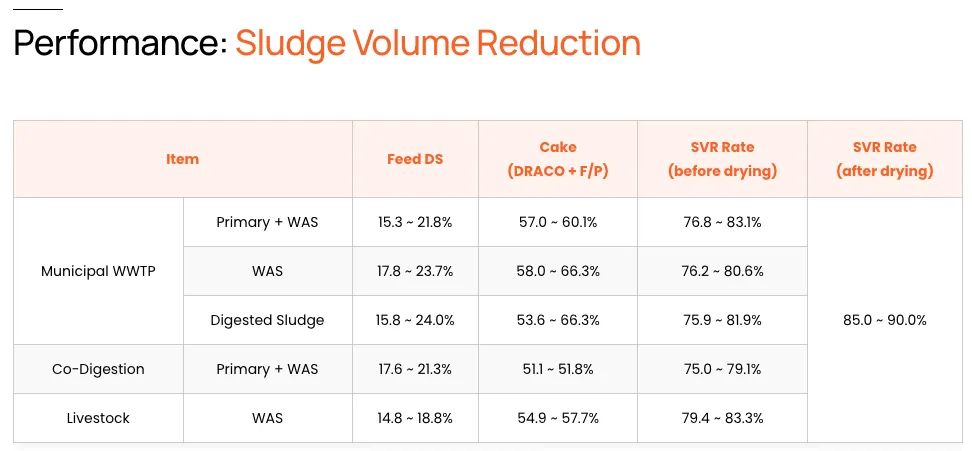

DRACO is a HydroThermal Carbonization (HTC) solution for sludge volume reduction. It reduces sludge volume by 80% and up to 90% with a dryer preventing sticky phase reducing overall energy costs.

When combined with an anaerobic digestor, DRACO system increases biogas production by over 30%.

DRACO can also be integrated with heat-generating plants such as incinerators, coal-fired power plants, and cement plants. By utilizing waste steam from these facilities as a heat source, it operates without the need for external energy input.

In addition, DRACO retrofits existing sludge dryer process, eliminating sticky phase issues, stabilizing dryer operation, and reducing 70% of energy costs.

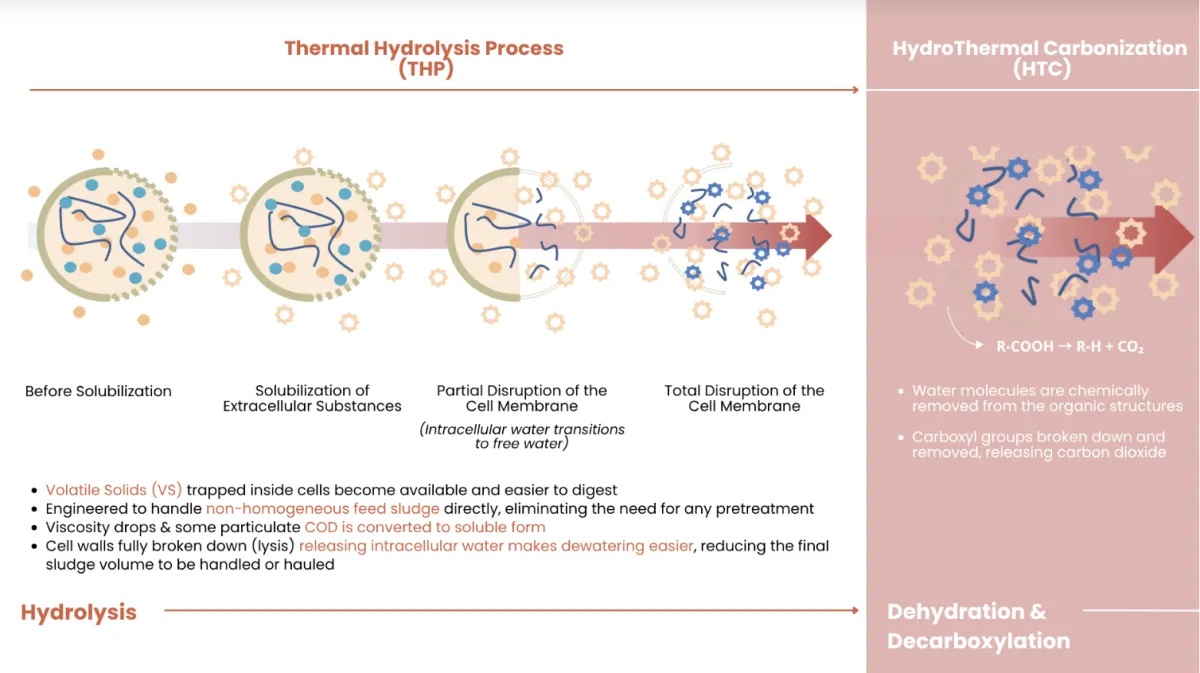

Don’t be surprised — DRACO can operate as either THP or HTC, depending on your objectives and configuration. It’s designed to adapt, not compromise.

DRACO HTC & DRACO THP

DRACO HTC undergoes the same initial hydrolysis phase as DRACO THP, followed by dehydration and decarboxylation to complete the reaction process

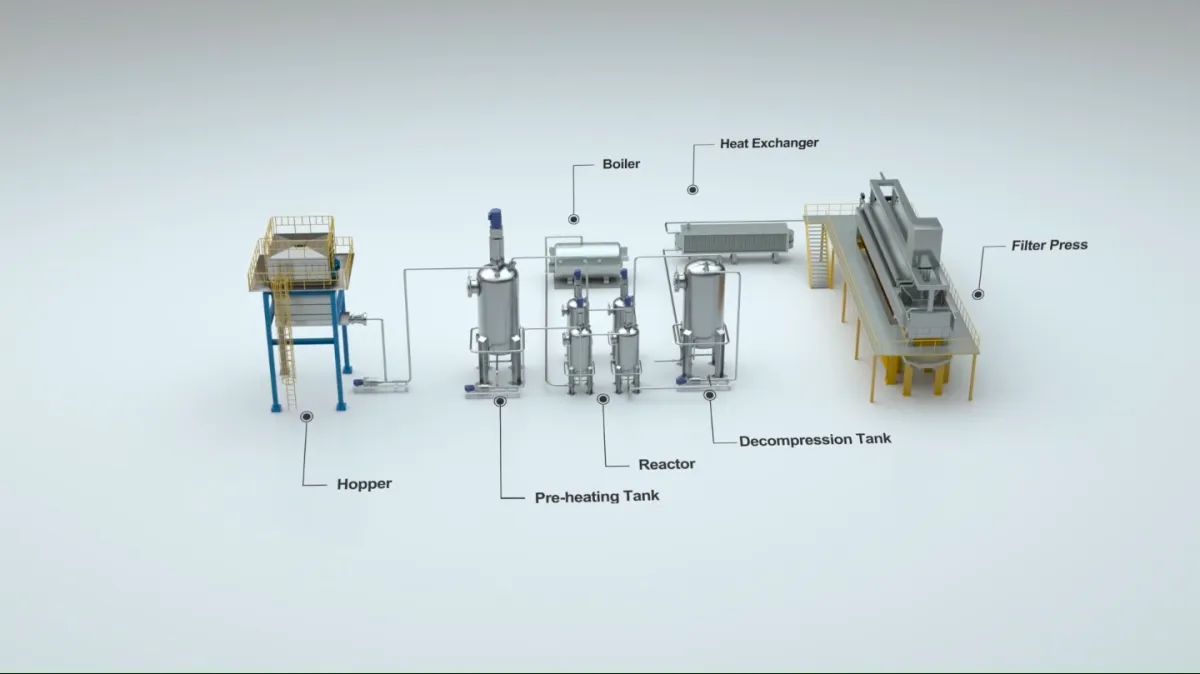

DRACO System Configuration

DRACO is a patented HTC system using a batch process with stepwise heating, pressurizing, cooling, and depressurizing of biosolids. Components include: Hopper, Pre-heating Tank, Reactors, Decompression Tank, Heat Exchanger, and a Filter Press line.

DRACO can process sludge regardless of water content through effective mixing and high heat transfer efficiency, using a patented multi-point steam injection technology.

- Improved contact between sludge & steam through the use of an agitator

- Enhanced heat transfer efficiency through patented multi-point steam injection technology

- Uniform heat distribution enables complete reaction of organic waste

- Heat transfer efficiency validated through 3D flow analysis

READY TO GIVE US A TRY?

Interested in these DRACO Systems?

Learn More About The DRACO System

DRACO Thermal Hydrolysis: Boosting Biogas Production 30%+ While Reducing Digestate Volumes for Energy Recovery Facilities in Florida

DRACO thermal hydrolysis boosts biogas production 30%+ while reducing digestate volumes 75%. Proven technology for wastewater plants and energy facilities. A perfect fit for facilities in Tampa, Flori... ...more

Waste Water Treatment Solutions ,sludge management &Biogas Production

September 28, 2025•17 min read

DRACO Thermal Hydrolysis: Solving the Sticky Phase Problem for Florida's Biosolids-to-Fertilizer Operations

DRACO thermal hydrolysis eliminates sticky phase problems in Florida biosolids processing. Achieve 75-85% volume reduction with chemical-free Class A treatment. ...more

Waste Water Treatment Solutions ,sludge management &Biogas Production

September 28, 2025•12 min read

Innovation

Fresh, creative solutions.

Integrity

Honesty and transparency.

Excellence

Top-notch services.

FOLLOW US

TECHNOLOGY & SERVICES

ABOUT US

CUSTOMER CARE

LEGAL

Copyright 2026. Carver Water . All Rights Reserved.