DRACO Thermal Hydrolysis: Boosting Biogas Production 30%+ While Reducing Digestate Volumes for Energy Recovery Facilities

The Energy Recovery Challenge: Maximizing Biogas While Minimizing Waste

Energy recovery facilities across the Southeast face dual pressures that are squeezing operational margins and limiting growth potential. Rising disposal costs for digestate and biosolids are eating into revenue, while energy markets demand maximum biogas production to remain competitive. Traditional anaerobic digestion systems, operating at standard parameters, leave significant energy potential untapped while generating substantial volumes of material requiring costly disposal.

Wastewater treatment plants from Florida to North Carolina process millions of gallons daily, generating biosolids that represent both a disposal challenge and an underutilized energy resource. Current anaerobic digestion systems typically achieve 40-50% volatile solids destruction, leaving substantial organic matter in digestate that could be converted to valuable biogas. Meanwhile, digestate volumes often exceed facility handling capacity, requiring expensive off-site disposal or land application programs.

Schedule a free biogas optimization assessment for your energy recovery operation.

The economic impact is substantial. A typical 10 MGD wastewater treatment plant generates 40-60 wet tons of biosolids daily. At disposal costs of $65-85/wet ton, annual disposal expenses reach $950,000-1,850,000. Simultaneously, suboptimal biogas production means lost revenue of $100,000-300,000 annually in potential energy generation. These facilities need technology that addresses both challenges simultaneously - increasing energy recovery while dramatically reducing waste volumes.

DRACO Technology: Dual-Mode Solutions for Energy Optimization

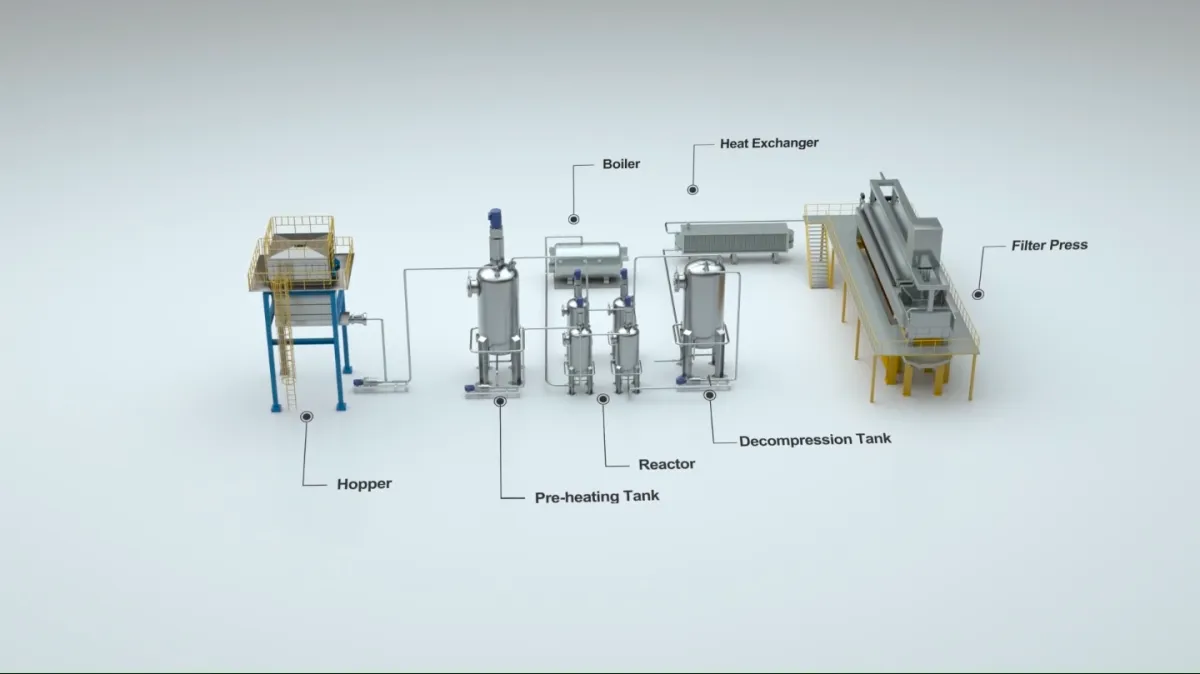

Tomorrow Water's DRACO (Destructive Reduction and Carbonization) technology offers two distinct configurations specifically designed for energy recovery applications: Thermal Hydrolysis Process (THP) for biogas enhancement and HydroThermal Carbonization (HTC) for volume reduction. Both processes can be integrated into existing facilities to optimize energy recovery and reduce operational costs.

DRACO THP: Pre-Digestion Biogas Enhancement

Operating Parameters for Maximum Biogas Production:

Temperature: <170°C optimized for cellular breakdown

Pressure: ~7 bar for controlled hydrolysis

Reaction time: 20 minutes for optimal organic matter release

Input flexibility: Processes thickened sludge at 16-18% dry solids

Integration: Pre-treatment before anaerobic digestion

Proven Performance Results:

Biogas increase: >30% methane production improvement documented

Digester efficiency: Doubles loading rates while reducing HRT

Volatile solids destruction: Enhanced breakdown from 45% to 65%+

Digester capacity: Existing digesters handle 2x throughput

The science behind these improvements lies in DRACO THP's ability to rupture cell walls and break down complex organic polymers that are typically resistant to anaerobic digestion. This pre-treatment makes organic matter more bioavailable to methanogenic bacteria, accelerating the conversion process and increasing overall biogas yields.

Get detailed biogas production projections for your specific organic waste streams.

DRACO HTC: Post-Digestion Volume Reduction

Operating Parameters for Maximum Volume Reduction:

Temperature: >190°C for optimal carbonization

Pressure: ~12 bar for complete transformation

Reaction time: 30 minutes for thorough processing

Application: Post-digestion digestate processing

Output: 75%+ volume reduction achieved

Volume Reduction Performance:

Digestate processing: Handles post-AD material at 15-25% dry solids

Final dewatering: Achieves 50-66% dry solids cake

Volume reduction: 75-85% reduction in material requiring disposal

Quality improvement: Pathogen-free Class A biosolids for beneficial use

This configuration addresses the backend challenge of digestate management while producing a valuable fertilizer product that can generate additional revenue or eliminate disposal costs entirely.

Southeastern Energy Recovery Market Applications

Wastewater Treatment Plant Optimization

The Southeast's growing population and industrial development are driving increased wastewater generation and more stringent environmental regulations. Energy recovery from biosolids represents both a compliance strategy and a revenue opportunity for municipal utilities.

Current Regional Challenges:

Energy costs: Rising electricity and natural gas prices affecting operational budgets

Disposal restrictions: Tightening regulations on biosolids land application

Capacity constraints: Growing populations exceeding digester capacity

Revenue pressure: Need for cost-neutral or revenue-positive operations

Environmental goals: Municipal commitments to carbon neutrality and renewable energy

DRACO THP Benefits for WWTPs:

Energy independence: 30%+ biogas increase moves facilities toward energy neutrality

Capacity expansion: Double existing digester throughput without new construction

Disposal cost reduction: Enhanced digestion reduces volatile solids requiring disposal

Revenue generation: Excess biogas for sale or renewable natural gas production

Regulatory compliance: Class A biosolids production for expanded beneficial use options

Economic Impact Analysis: A 10 MGD wastewater treatment plant with existing anaerobic digestion:

Current biogas: ~15,000 ft³/day at 60% methane content

DRACO THP enhancement: ~20,000 ft³/day biogas production

Additional energy: 1,200 kWh/day additional electricity generation

Annual value: $130,000-180,000 in additional energy revenue

Calculate energy recovery potential for your wastewater treatment facility.

Industrial and Agricultural Energy Recovery

Food processing facilities, agricultural operations, and industrial manufacturers generate substantial organic waste streams that represent untapped energy resources. DRACO technology enhances the economics of anaerobic digestion for these applications while solving waste management challenges.

Food Processing Applications:

Brewery waste: Enhanced biogas from spent grains and yeast

Dairy processing: Increased methane from whey and dairy solids

Meat processing: Improved digestion of high-protein waste streams

Produce processing: Better breakdown of fibrous vegetable waste

Agricultural Integration:

Livestock operations: Enhanced biogas from manure and bedding materials

Crop residue processing: Better utilization of agricultural waste

Energy crop optimization: Improved economics for dedicated energy crops

Co-digestion benefits: Enhanced performance from mixed waste streams

Industrial Waste Streams:

Paper mills: Enhanced biogas from fiber and biological sludges

Chemical processing: Better treatment of high-strength organic waste

Pharmaceutical manufacturing: Improved processing of biological waste

Textile operations: Enhanced treatment of organic dyes and fibers

Landfill and Waste Management Operations

Landfill operators and waste management companies face increasing pressure to capture methane emissions while managing organic waste volumes. DRACO technology offers solutions for both existing landfill gas enhancement and alternative organic waste processing.

Landfill Gas Enhancement:

Pre-processing: Treatment of organic waste before landfill placement

Gas capture optimization: Enhanced methane generation from treated organics

Leachate reduction: Lower moisture content reduces leachate generation

Airspace conservation: Volume reduction extends landfill life

Alternative Processing:

Diversion programs: Process organic waste before landfill disposal

Energy recovery facilities: Dedicated biogas production from municipal organics

Composting enhancement: Improved decomposition and reduced odors

Transportation optimization: Volume reduction reduces collection costs

Explore waste-to-energy opportunities for your waste management operation.

Technical Advantages: Proven Performance Data

Laboratory and Pilot Scale Validation

DRACO technology has undergone extensive testing and validation through pilot plant operations processing 2 wet tons/day of various organic waste streams. This comprehensive testing program provides reliable performance data for full-scale implementation planning.

Post-AD HTC Performance Data:

Continuous operation: 27-day hydraulic retention time vs. 30 days conventional

Methane production: 2.0 L/d vs. 1.5 L/d for conventional digestion alone

Volume reduction: >75% reduction in digestate volume

Process stability: Consistent performance across varying feedstock conditions

Feedstock Flexibility Testing:

Municipal biosolids: Primary, WAS, and digested sludge processing

Industrial waste: Food processing and manufacturing organic streams

Agricultural waste: Livestock manure and crop residue processing

Co-digestion streams: Mixed organic waste optimization

Full-Scale Commercial Installations

Daejeon WWTP, Korea (Under Construction):

Capacity: 495 wet tons/day DRACO THP installation

Application: Pre-AD biogas enhancement for municipal WAS

Design parameters: 25-day anaerobic digestion HRT

Expected results: 30%+ biogas increase with enhanced volatile solids destruction

Gimhae Facility, Korea (Operating Since 2019):

Capacity: 100 wet tons/day DRACO HTC operation

Application: Volume reduction without anaerobic digestion

Results: 80%+ volume reduction for mixed municipal and industrial waste

Benefits: Elimination of disposal costs and production of Class A biosolids

Seosan Project, Korea (Commissioning 2025):

Capacity: 100 wet tons/day for drying performance improvement

Integration: DRACO HTC with thermal drying for solid fuel production

Innovation: Combined volume reduction and energy recovery approach

Performance: 87% overall volume reduction with energy co-production

Access detailed case study performance data for technology validation.

Energy Recovery Economics: ROI Through Enhanced Production

Biogas Revenue Enhancement

Direct Energy Value Calculation: For a facility producing 15,000 ft³/day of biogas at current rates:

Current energy value: ~9,000 kWh/day at $0.12/kWh = $1,080/day

DRACO THP enhancement: +30% = 12,000 kWh/day total

Additional revenue: $360/day or $131,000/year additional energy value

Investment payback: 2-4 years typical for THP installations

Renewable Natural Gas Opportunities: Enhanced biogas production creates opportunities for renewable natural gas (RNG) development:

Pipeline injection: Upgraded biogas for natural gas grid injection

Vehicle fuel: Compressed RNG for fleet applications

Premium pricing: RNG commands $15-25/MMBtu vs. $4-6/MMBtu for conventional natural gas

Carbon credits: Additional revenue from greenhouse gas emission reductions

Energy Independence Benefits:

Grid independence: Reduced purchased electricity costs

Price stability: Protection from volatile energy market prices

Backup power: Enhanced energy security during grid outages

Peak shaving: Reduced demand charges through on-site generation

Calculate renewable energy revenue potential for your facility's biogas production.

Disposal Cost Elimination

Volume Reduction Economics: DRACO HTC processing dramatically reduces disposal costs through volume reduction:

Current disposal: 50 wet tons/day at $75/ton = $3,750/day

Post-DRACO: 10 wet tons/day at $75/ton = $750/day

Daily savings: $3,000/day or $1.1 million/year

Investment justification: Disposal savings alone justify DRACO installation

Transportation Cost Reduction:

Current transportation: 2-3 truck loads daily for digestate hauling

Post-processing: Single truck load every 2-3 days

Fuel savings: $200-300/day in reduced transportation costs

Labor efficiency: Reduced handling and logistics management

Land Application Benefits:

Class A biosolids: Expanded beneficial use opportunities

Reduced application rates: Higher solids content requires less material handling

Extended storage: Pathogen-free material allows longer storage periods

Premium pricing: Class A material commands higher value than Class B

Operational Efficiency Gains

Digester Optimization:

Capacity increase: 2x throughput from existing digester infrastructure

Reduced foaming: THP treatment reduces digester foaming issues

Improved mixing: Better material characteristics improve digester performance

Extended equipment life: Reduced stress on existing equipment

Maintenance Reduction:

Reduced viscosity: Lower pumping energy and reduced equipment wear

Pathogen elimination: Reduced biological fouling and corrosion

Improved dewatering: Less polymer consumption and improved cake quality

Process stability: More consistent operations with reduced variability

Implementation Strategies: Technology Integration Options

Retrofit Applications

Pre-AD THP Integration: Most existing anaerobic digestion facilities can be retrofitted with DRACO THP technology:

Upstream integration: Install before existing digesters

Minimal disruption: Phased installation during planned maintenance

Utility integration: Steam generation from existing boiler systems

Control system: Integration with existing SCADA and control systems

Post-AD HTC Integration: For facilities prioritizing volume reduction:

Downstream processing: Install after existing digestion

Independent operation: Can operate separately from digestion systems

Flexible scheduling: Process digestate as generated or in batches

Product handling: Integration with existing dewatering equipment

New Facility Design

Integrated System Design: New energy recovery facilities can optimize DRACO integration:

Combined heat and power: Biogas utilization for steam generation

Heat recovery: Process heat integration for maximum efficiency

Automated operation: Full automation from feedstock to final product

Modular expansion: Design for future capacity increases

Utility Optimization:

Steam generation: Sizing boiler systems for DRACO requirements

Electrical integration: Power requirements and grid connection

Water systems: Process water and cooling requirements

Waste heat recovery: Maximum energy efficiency through heat integration

Get system integration consultation for retrofit or new facility design.

Phased Implementation

Stage 1: Assessment and Design

Feedstock characterization: Testing of specific organic waste streams

Performance modeling: Projected biogas increases and volume reductions

Economic analysis: ROI calculations and financing options

Regulatory planning: Permitting requirements and approvals

Stage 2: Pilot Testing (when required)

Small-scale validation: Proof of concept using actual facility waste

Performance verification: Confirm projected results before full-scale investment

Optimization studies: Fine-tune operating parameters for maximum efficiency

Operator training: Hands-on experience with technology

Stage 3: Full-Scale Implementation

Equipment installation: Professional installation and commissioning

System integration: Connection with existing facility systems

Performance testing: Validation of guaranteed performance parameters

Ongoing optimization: Continuous improvement and support

Environmental and Regulatory Benefits

Greenhouse Gas Reduction

Methane Capture Enhancement:

Increased biogas recovery: 30%+ improvement in methane capture from organic waste

Reduced fugitive emissions: Better digestion reduces methane release

Carbon credit potential: Greenhouse gas reduction credits available

Corporate sustainability: Support for carbon neutrality commitments

Lifecycle Environmental Benefits:

Fossil fuel displacement: Biogas replaces natural gas and electricity from fossil sources

Transportation reduction: Volume reduction reduces truck trips and emissions

Land application: Class A biosolids provide carbon sequestration benefits

Circular economy: Waste-to-energy exemplifies circular economy principles

Regulatory Compliance Advantages

EPA Part 503 Compliance:

Class A pathogen elimination: Thermal treatment exceeds pathogen reduction requirements

Vector attraction reduction: Volatile solids destruction meets VAR requirements

Heavy metals compliance: No chemical additions that could introduce contaminants

Land application flexibility: Class A status expands beneficial use options

State and Local Regulations:

Air quality: Reduced emissions from enhanced biogas capture

Water quality: Improved biosolids quality reduces groundwater concerns

Waste management: Volume reduction supports waste diversion goals

Renewable energy: Supports state renewable energy mandates

Get regulatory compliance assessment for your jurisdiction's requirements.

Regional Support and Implementation Services

Comprehensive Project Management

Pre-Implementation Support:

Feasibility studies: Detailed technical and economic analysis

Technology selection: THP vs. HTC configuration optimization

Regulatory support: Permitting assistance and agency coordination

Financing assistance: Capital planning and funding source identification

Installation and Commissioning:

Project management: Dedicated team for seamless implementation

Quality assurance: Certified installation procedures and testing

System integration: Professional integration with existing systems

Performance validation: Guaranteed performance testing and certification

Ongoing Support:

24/7 emergency support: Immediate response for critical operations

Preventive maintenance: Scheduled maintenance programs for optimal performance

Performance optimization: Continuous improvement consulting and support

Technology updates: Access to latest developments and improvements

Southeast Regional Expertise

Local Market Knowledge:

Waste characteristics: Understanding of regional organic waste streams

Regulatory environment: Knowledge of state and federal requirements

Utility relationships: Established connections with regional utilities

Service network: Local contractors and service providers

Industry Experience:

Municipal utilities: Experience with wastewater treatment plant operations

Industrial facilities: Knowledge of food processing and manufacturing waste

Agricultural operations: Understanding of livestock and crop processing waste

Landfill operations: Experience with waste management and gas capture

Connect with regional experts for immediate project support.

Next Steps: Optimize Your Energy Recovery Operation

Assessment and Planning Process

Energy Recovery Audit:

Current performance analysis: Evaluation of existing biogas production and utilization

Waste stream characterization: Analysis of organic waste composition and volumes

Economic baseline: Current energy costs and disposal expenses

Optimization opportunities: Identification of improvement potential

Technology Selection:

THP vs. HTC evaluation: Optimal configuration for your specific application

Integration planning: Seamless connection with existing systems

Performance projections: Guaranteed results based on your waste characteristics

Investment analysis: Detailed ROI calculations and financing options

Implementation Planning:

Project timeline: Phased approach minimizing operational disruption

Regulatory strategy: Permit applications and agency approvals

Construction planning: Site preparation and utility requirements

Training program: Operator certification and ongoing support

Begin your energy optimization assessment today.

Investment and Financing Solutions

Capital Investment Analysis:

Equipment costs: Complete system pricing for your capacity requirements

Installation expenses: Turnkey project costs including integration

Operating expenses: Energy, maintenance, and labor requirements

Revenue enhancement: Biogas value increase and disposal cost savings

Financing Options:

Traditional financing: Equipment loans and leasing programs

Performance contracts: Payment based on energy production and cost savings

Power purchase agreements: Third-party ownership with energy sales

Grant funding: State and federal incentives for renewable energy projects

Risk Management:

Performance guarantees: Contractual commitments for energy production improvements

Technology insurance: Protection against equipment performance issues

Regulatory compliance: Guaranteed permit approval and ongoing compliance support

Market protection: Long-term energy pricing agreements when available

Emergency Response and Rapid Implementation

Critical Situation Support: For facilities experiencing immediate energy production or waste management challenges:

Emergency assessment: Rapid evaluation of critical issues

Temporary solutions: Mobile equipment and process modifications

Expedited installation: Fast-track implementation for urgent needs

Crisis management: Complete support during emergency situations

Rapid Implementation Programs:

Pre-engineered systems: Standard configurations for quick deployment

Expedited permitting: Streamlined regulatory approval processes

Accelerated installation: Compressed timeline implementation

Immediate support: Enhanced support during startup and optimization

Contact emergency response team for urgent energy recovery challenges.

Conclusion: Transforming Waste into Valuable Energy Resources

DRACO thermal hydrolysis technology represents a proven solution for energy recovery facilities seeking to maximize biogas production while minimizing waste management costs. Whether implemented as pre-digestion treatment for enhanced biogas yields or post-digestion processing for dramatic volume reduction, DRACO technology delivers measurable improvements in both energy production and operational efficiency.

Immediate Impact:

30%+ biogas increase: Significant enhancement in energy production and revenue

75%+ volume reduction: Dramatic reduction in disposal costs and logistics

Class A biosolids: High-value fertilizer product with expanded market opportunities

Process optimization: Improved digester performance and operational stability

Long-term Value:

Energy independence: Reduced reliance on purchased electricity and natural gas

Revenue diversification: Multiple income streams from energy and fertilizer products

Environmental leadership: Significant greenhouse gas reductions and sustainability benefits

Operational efficiency: Reduced maintenance, labor, and management requirements

The Southeast's growing focus on renewable energy, combined with increasing pressure to manage organic waste sustainably, creates an ideal environment for DRACO technology adoption. Facilities that implement this proven technology today will benefit from enhanced energy production, reduced operational costs, and improved environmental performance that positions them as leaders in the transition to a circular economy.

Schedule your comprehensive energy recovery assessment to discover how DRACO thermal hydrolysis can transform your waste management challenges into profitable energy opportunities.

Carver Water Technology serves as the authorized regional partner for Tomorrow Water's innovative DRACO thermal hydrolysis technology throughout the Southeastern United States. Our experienced team provides comprehensive support from initial feasibility analysis through full-scale implementation and ongoing optimization, ensuring your energy recovery operation achieves maximum efficiency and profitability while contributing to a sustainable energy future.