Wastewater Treatment

Industrial Wastewater Treatment in Tampa, FL

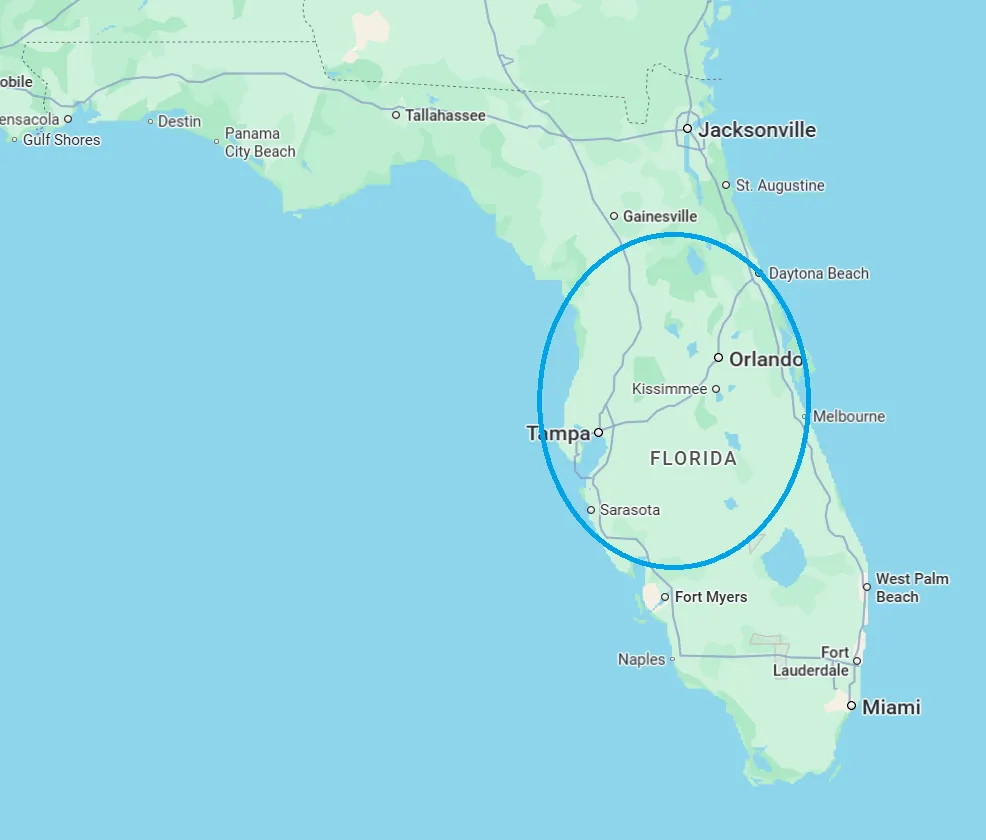

Primary Service Area: Tampa • Clearwater • St. Petersburg

Same-Day Service Available Across Tampa Bay

Carver Water Technology delivers engineering-grade industrial wastewater solutions across Tampa Bay. From high-strength brewery effluent and manufacturing process water to mobile home and RV park treatment systems, we design, install, and maintain systems to meet regulatory compliance, efficiency, and operational reliability. Our team also provides operator support for facilities that require daily management or on-call expertise.

Water Treatment

Solutions

Expert Contaminant Removal In The US and The Caribbean

When water quality threatens operations, compliance, or safety, Carver Water Technology delivers proven solutions. From municipal utilities to industrial facilities, we've built our reputation on eliminating contaminants that disrupt business, damage equipment, and violate drinking water standards.

Based in Tampa with coverage across the Southeastern United States and the Caribbean, our team of water treatment professionals responds to your water challenges with the same urgency you face—because we know that in your business, water problems don't wait.

Why Industrial Facilities in Tampa Need Expert Wastewater Solutions

Tampa’s industrial and commercial facilities face unique wastewater challenges:

High-strength waste streams from breweries, food & beverage, and manufacturing operations

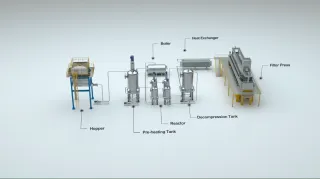

Solids and organics that require advanced treatment like DRACO thermal hydrolysis or Proteus biofiltration

Nitrogen removal and regulatory compliance handled by AMX systems

Smaller, dispersed facilities such as RV parks and mobile home communities often lack trained operators

Our solutions ensure your facility remains compliant, efficient, and cost-effective, whether it’s a high-volume industrial site or a community-scale treatment system.

Industries That Require Wastewater Discharge Treatment

Landfills & Leachate Treatment

Landfill leachate contains extreme ammonia concentrations, recalcitrant organics, and toxic compounds that are difficult to treat with conventional processes. We implement advanced biological and nutrient-removal systems to reduce nitrogen, protect downstream infrastructure, and meet strict discharge limits.

Private & Municipal Utilities

Including mobile home parks, RV parks, HOAs, and private developments operating their own wastewater infrastructure.

We support:

Package wastewater treatment plants

Flow equalization and wet weather capacity

Nutrient removal (BNR, nitrogen, phosphorus)

Operator support and compliance management

Car Washes, Fleet Washing & Transportation Facilities

Wash water contains detergents, oils, grit, and hydrocarbons.

We design systems for:

Oil-water separation

Solids removal

Recycle and reuse

Sewer or surface discharge compliance

Breweries and & Beverage Facilities

Breweries and beverage facilities generate high-strength wastewater with elevated BOD, COD, suspended solids, and pH variability that frequently exceeds municipal discharge limits. We design and operate pretreatment and biological systems that stabilize loads, reduce surcharges, and maintain regulatory compliance during peak production.

Manufacturing & Industrial Processing

Industrial manufacturing wastewater varies widely in chemistry and often includes metals, solvents, nutrients, and fluctuating loads that require custom treatment strategies. We design site-specific systems that manage variability, protect municipal sewers, and ensure long-term regulatory compliance.

Semiconductor & Electronics Manufacturing

Ultra-clean manufacturing creates highly contaminated wastewater containing acids, solvents, metals, and ammonia.

We provide solutions for:

Metals removal

Nitrogen reduction

pH neutralization

Advanced biological and physical treatment systems

Agriculture & Aquaculture

Agricultural operations generate nutrient-rich wastewater requiring controlled treatment.

We support:

Nutrient and solids reduction

Lagoon upgrades and pretreatment

Aquaculture effluent treatment

Reuse strategies where permitted

Food Processing

Food, meat, poultry, and seafood processors produce wastewater high in fats, oils, grease, ammonia, and organic loading that can overwhelm conventional treatment. Our engineered solutions address solids separation, nutrient removal, odor control, and biological stability for consistent permit compliance.

Steam Generation & Power

Boiler blowdown, cooling tower blowdown, and chemical cleaning waste streams require treatment before discharge or reuse.

We support industrial wastewater systems handling:

High-TDS and high-temperature waste streams

Pharmaceutical, Cannabis And Medical Manufacturing

These facilities generate complex, high-strength wastewater from CIP systems, solvents, nutrients, and regulated compounds.

We design and support systems for:

GMP-compliant wastewater management

Nutrient and COD reduction

Pretreatment for municipal discharge approval

On-site treatment for sensitive compounds

Our Industrial Wastewater Services in Tampa

1. System Design & Engineering

Custom solutions using Proteus, AMX, DRACO, and other advanced wastewater technologies

Engineering for site-specific flow rates, effluent quality, and local discharge regulations

Optimization for energy recovery and biosolids management

2. Installation & Commissioning

Complete installation, piping, electrical, instrumentation, and control integration

System startup, calibration, and operator training

Tailored to industrial facilities, breweries, and niche operators like RV and mobile home parks

3. Operator & Maintenance Support

On-site or remote daily operations support

Preventive maintenance, membrane cleaning, chemical dosing, and equipment calibration

24/7 emergency response to protect compliance and system performance

4. Mobile & Niche Facility Solutions

RV parks, mobile home communities, and small commercial facilities

Turnkey operator services for facilities without dedicated wastewater staff

Compliance-focused solutions designed for low-footprint, high-performance systems

Tampa Plant Engineering & Design

For Tampa projects, our engineering team handles:

Feed water analysis

Pretreatment selection

Concentrate disposal

Controls, monitoring, and SCADA where required

P&IDs and process flow diagrams

Equipment specifications and procurement

Electrical and controls design

Structural and civil requirements

Permitting and regulatory compliance support

Carver Water Technology designs, installs, and maintains industrial and commercial wastewater treatment systems for facilities ranging from small mobile home and RV parks to large breweries, manufacturing plants, and processing facilities.

Our pre-engineered modular wastewater systems, suitable for smaller facilities up to medium-scale industrial operations, are available for fast deployment and can be customized to meet your site-specific treatment requirements.

Our expertise includes system troubleshooting, preventive maintenance, chemical dosing optimization, and operator training to ensure your facility stays compliant, efficient, and cost-effective.

With same-day service in Tampa and across Florida, we make sure your wastewater systems perform reliably whenever you need them.

Our Same-Day

Service Area

Primary Service Areas:

Tampa, South Tampa, Westchase, Carrollwood, Temple Terrace

Brandon, Riverview, Valrico, Seffner, Thonotosassa

Lutz, Wesley Chapel, Odessa, Cheval

St. Petersburg, Gulfport, Kenneth City, Tierra Verde, Pinellas Park

Clearwater, Palm Harbor, Safety Harbor, Dunedin, Belleair

New Port Richey, Holiday, Bayonet Point, Port Richey

Emergency Service: 24/7 across Central Florida

Local Case Studies & Proof of Expertise

Preventative Maintenance for Water Systems: Reducing Downtime and Costly Failures

New Blog Post Description ...more

Water System Repairs ,Plant Automation Waste Water Treatment Solutions &Plant Operation

January 08, 2026•3 min read

Carver Water Technology Commissions Advanced MBBR Wastewater System in Runaway Bay, Jamaica

Carver Water Technology is bringing cutting-edge wastewater treatment to Jamaica's North Coast through a strategic partnership with Isratech Jamaica. This 300 m³/day MBBR (Moving Bed Biofilm Reactor) ... ...more

Waste Water Treatment Solutions ,Caribbean

December 17, 2025•13 min read

DRACO Thermal Hydrolysis: Boosting Biogas Production 30%+ While Reducing Digestate Volumes for Energy Recovery Facilities in Florida

DRACO thermal hydrolysis boosts biogas production 30%+ while reducing digestate volumes 75%. Proven technology for wastewater plants and energy facilities. A perfect fit for facilities in Tampa, Flori... ...more

Waste Water Treatment Solutions ,sludge management &Biogas Production

September 28, 2025•17 min read

DRACO Thermal Hydrolysis: Solving the Sticky Phase Problem for Florida's Biosolids-to-Fertilizer Operations

DRACO thermal hydrolysis eliminates sticky phase problems in Florida biosolids processing. Achieve 75-85% volume reduction with chemical-free Class A treatment. ...more

Waste Water Treatment Solutions ,sludge management &Biogas Production

September 28, 2025•12 min read

Why Your Water Treatment Vendor Is Costing Your Brewery Money (And How to Fix It)

Stop losing production to unreliable water treatment vendors. Brewery-specific solutions, 24/7 emergency response, vendor-independent systems. Free brewery vendor audit available. ...more

Water System Repairs ,Waste Water Treatment Solutions Reverse Osmosis & Deionization &Food & Beverage

September 28, 2025•5 min read

Turn Waste Into Energy with DRACO Thermal Hydrolysis

As cities, utilities, and industries face rising waste management costs and mounting environmental pressures, the push for innovative and sustainable solutions has never been greater. One of the most ... ...more

Waste Water Treatment Solutions

September 17, 2025•3 min read

Wastewater System Resources & Support

Knowledge Center:

(COMING SOON) Case studies and project examples

Frequently Asked Questions

Q1: Do you provide operator support for small facilities like RV parks?

Yes. Our trained operators manage daily operations, preventive maintenance, and emergency troubleshooting.

Q2: Can you retrofit older wastewater systems in mobile home parks?

Absolutely. We specialize in upgrading and optimizing existing systems for efficiency and compliance.

Q3: How quickly can we get emergency service in Tampa?

Most Tampa Bay facilities receive same-day emergency support, 24/7.

Q4: Do you handle high-strength brewery or industrial wastewater?

Yes. We engineer treatment systems for high-strength industrial effluent, including solids, organics, and nitrogen removal.

Q5: Do you service systems not originally installed by Carver Water?

Yes. We service and optimize systems regardless of original manufacturer.

Q7: What are the biggest challenges with DEP compliance?

The main challenges with Florida DEP compliance for industrial wastewater facilities include:

Effluent quality limits: Meeting strict limits for nutrients (nitrogen, phosphorus), BOD, TSS, and other regulated parameters can be difficult for high-strength or variable waste streams.

Permit management: Navigating and maintaining discharge permits, reporting schedules, and recordkeeping is complex, especially for facilities with multiple outfalls.

Operator qualification: Facilities must have trained operators on site or under contract to meet DEP staffing and certification requirements.

System reliability: Older or poorly designed treatment systems often fail to consistently meet DEP standards, creating regulatory risk.

Monitoring and reporting: Continuous monitoring and timely reporting are required; missing data or errors can trigger fines.

Technology adaptation: Implementing advanced processes like AMX, Proteus, or DRACO systems correctly to meet DEP standards can require specialized expertise.

Bottom line: Staying compliant requires properly engineered systems, trained operators, and ongoing monitoring, which is why many industrial and niche facilities partner with experienced wastewater engineering firms like Carver Water Technology.

👉 Still have questions?

We're Here To Help!

Schedule a Tampa Industrial Wastewater Consultation

Talk directly with our engineering team about:

Tampa water quality challenges

Flow and purity requirements

Budget and timeline

Long-term maintenance planning

Innovation

Fresh, creative solutions.

Integrity

Honesty and transparency.

Excellence

Top-notch services.

FOLLOW US

TECHNOLOGY & SERVICES

ABOUT US

CUSTOMER CARE

LEGAL

Copyright 2026. Carver Water . All Rights Reserved.