Reverse Osmosis

Carver Water Is Tampa's Premier RO Design, Installation & Service Provider

Primary Service Area: Tampa • Clearwater • St. Petersburg

Same-Day RO Service Available Across Tampa Bay

Carver Water Technology provides engineering-driven reverse osmosis systems for Tampa Bay businesses, municipalities, and critical facilities. From compact commercial RO units to large-scale brackish water systems, we design, install, and maintain RO systems engineered specifically for Tampa water chemistry and operating conditions.

Water Treatment

Solutions

Expert Contaminant Removal In The US and The Caribbean

When water quality threatens operations, compliance, or safety, Carver Water Technology delivers proven solutions. From municipal utilities to industrial facilities, we've built our reputation on eliminating contaminants that disrupt business, damage equipment, and violate drinking water standards.

Based in Tampa with coverage across the Southeastern United States and the Caribbean, our team of water treatment professionals responds to your water challenges with the same urgency you face—because we know that in your business, water problems don't wait.

INTRODUCING

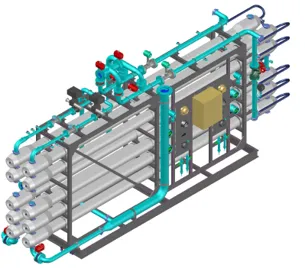

Standard Commercial BWRO Systems

(2,500 GPD - 15,000 GPD)

Compact Design -

Ready To Ship from Tampa!

The #1 choice for small businesses

100% risk free - 30 day money back guarantee

Applications

Restaurants & Breweries

Hotels

Small manufacturing facilities

Dialysis clinics

Car washes

Total value: $7,597

Starting at Just $5,950

INTRODUCING

Light Industrial BWRO and SWRO

(15,000 GPD - 175,000 GPD)

Applications:

Manufacturing

Food processing

Utilities

Total value: $25,997

Starting At Just $19,999

Custom Engineered Or Pre-Designed

Fabricated in Tampa, FL

The #1 choice for industrial applications

Payment Terms Available

INTRODUCING

Heavy Industrial & Municipal

BWRO & SWRO

(175,000 GPD - 500,000 GPD)

Custom Engineered or Pre-Designed

Fabricated in Tampa, FL

The #1 choice for large industrial enterprises

Payment Terms Available

Applications

Desalination

Power generation

Process water

Contact Us For A Quote

Tampa RO Engineering & Design

For Tampa projects, our engineering team handles:

Local source water analysis

Pretreatment selection for Tampa water conditions

Membrane selection based on fouling risk

Recovery optimization considering concentrate disposal

CIP system integration

Controls, monitoring, and SCADA where required

P&IDs and process flow diagrams

Equipment specifications and procurement

Electrical and controls design

Structural and civil requirements

Permitting and regulatory compliance support

Tampa Industries We Serve

Power, Steam & Boilers Systems

RO/DI feedwater systems preventing corrosion and scaling in commercial and industrial boilers throughout Hillsborough County.

Hospitals & Dialysis Centers

Hospital-grade RO and DI systems supporting sterilization, dialysis, and medical processes across Tampa Bay.

High-performance RO/DI systems delivering consistent spot-free rinse water for Tampa car washes.

Municipal Water Utilities

Drinking water treatment and desalination

Brackish groundwater treatment

Surface water polishing

Regulatory compliance (SDWA, state standards)

Carver Water Technology designs, installs, and maintains Brackish and Seawater RO systems ranging from small commercial units (2,500 GPD+) to large industrial and municipal systems (100,000+ GPD).

Our pre-designed Brackish Water RO units (BWRO) from 2,500 GPD to 15,000 GPD are for sale online now!

Our membrane expertise includes performance troubleshooting, cleaning protocols, and replacement strategies that maximize your investment.

Our same-day service in Tampa and across Florida ensures your Reverse Osmosis systems perform when you need them.

Installation & Same-Day RO Service in Tampa

RO Installation, Commissioning & Service Across Tampa Bay

We provide full-scope RO installation and lifecycle support:

Mechanical and electrical installation

Startup and commissioning

Operator training

Preventive maintenance programs

Membrane cleaning and replacement

24/7 emergency RO repair in Tampa Bay

Same-day service available in most Tampa locations.

Why Reverse Osmosis Is Critical in Tampa

Why Tampa Water Requires Engineered RO Solutions

Tampa Bay water sources present unique challenges that require properly designed RO systems:

Elevated dissolved solids depending on source

Hardness and scaling potential impacting membranes

Chloramines and organics affecting pretreatment

Regulatory compliance requirements for commercial and medical facilities

Generic RO systems fail early in these conditions.

We design pretreatment, membrane selection, and recovery rates specifically for Tampa installations.

Supporting Local Tampa Businesses

Carver Water supports local Tampa Businesses by providing commercial softener systems or servicing based on their needs. ...more

Water System Repairs ,Tampa

August 26, 2025•4 min read

When Every Hour Counts: How Mobile Water Treatment Protects Tampa Businesses

Discover how Carver Water Technology’s mobile water treatment systems safeguard Tampa businesses during outages, storms, and peak demand. Flexible, fast, and reliable. ...more

Emergency Water Systems ,Tampa

August 26, 2025•2 min read

Hillsborough County, Tampa Water System Repair | Carver Water Restores Trout Creek Park After Hurricane Milton

Carver Water restored the Trout Creek Park water system after Hurricane Milton. Discover how we replaced tanks, piping, and controls to bring safe water back to Hillsborough County, Tampa Florida ...more

Water System Repairs ,Tampa

August 19, 2025•3 min read

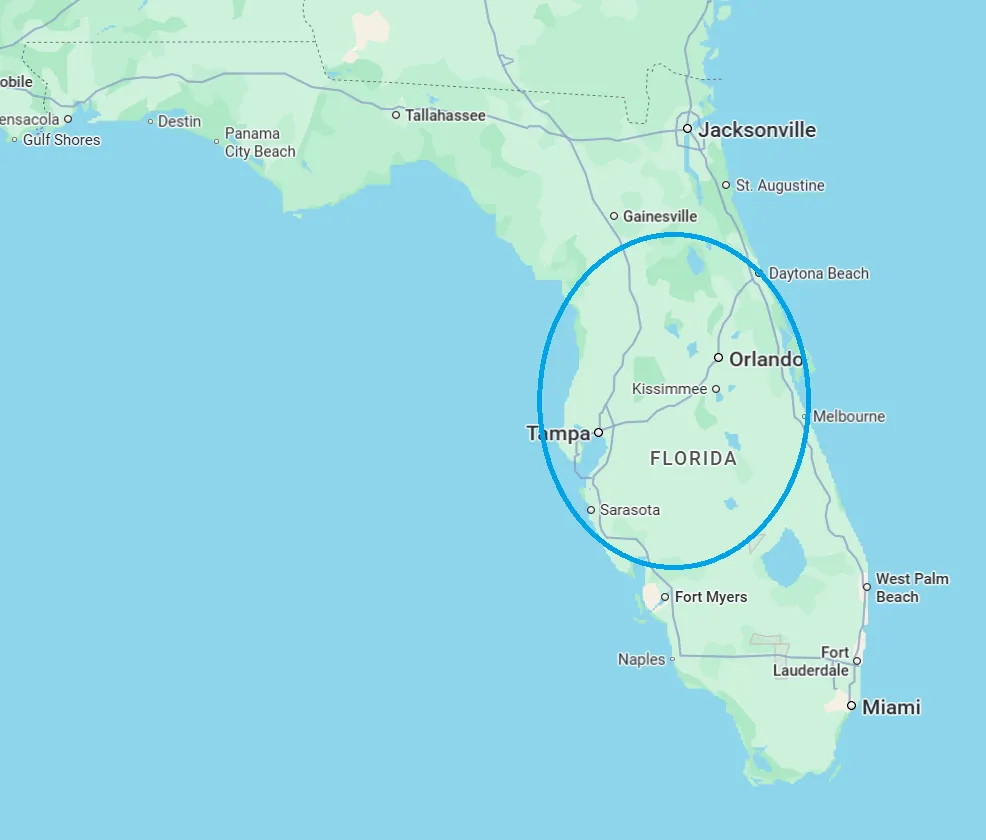

Our Same-Day

Service Area

Reverse Osmosis Systems Across Florida & Beyond

Primary Service Areas:

Tampa, South Tampa, Westchase, Carrollwood, Temple Terrace

Brandon, Riverview, Valrico, Seffner, Thonotosassa

Lutz, Wesley Chapel, Odessa, Cheval

St. Petersburg, Gulfport, Kenneth City, Tierra Verde, Pinellas Park

Clearwater, Palm Harbor, Safety Harbor, Dunedin, Belleair

New Port Richey, Holiday, Bayonet Point, Port Richey

Emergency Service: 24/7 across Central Florida

Global Shipping: Small RO systems (2,500+ GPD) and containerized systems (up to 144,000 GPD) ship worldwide

RO System Resources & Support

Knowledge Center:

(COMING SOON) RO maintenance best practices, troubleshooting guides, industry applications

Technical specifications and performance data

Case studies and project examples

Frequently Asked Questions

Q1: Do you provide emergency RO service in Tampa?

Yes. We offer 24/7 emergency RO repair across Tampa Bay and Central Florida.

Q2: How fast can an RO system be installed in Tampa?

Small commercial systems can often be installed and commissioned within days depending on site readiness.

Q3: How do PFAS typically enter drinking water systems?

PFAS contamination occurs through several pathways:

Industrial discharges from manufacturing plants.

Wastewater treatment plant effluent, which returns PFAS-laden water to rivers.

Firefighting foam (AFFF) runoff from military bases and airports.

Landfill leachate and biosolids applied to agricultural fields.

Atmospheric deposition from PFAS released through factory emissions.

Once PFAS reach surface water or groundwater, they spread widely and infiltrate municipal supplies.

Q4: Which PFAS treatment technologies are most effective?

There is no single “perfect” technology, but leading options include:

Granular Activated Carbon (GAC): Effective for long-chain PFAS like PFOA and PFOS, but less efficient for short-chain compounds such as GenX.

Ion Exchange (IX): Strong-base anion resins can remove both long- and short-chain PFAS, but resin fouling and PFAS-concentrated brine disposal remain challenges.

Reverse Osmosis (RO) and Nanofiltration (NF): RO provides comprehensive removal of nearly all PFAS, while NF is more energy-efficient but less effective on short-chain PFAS. Both generate brine waste streams requiring careful disposal.

Advanced Oxidation Processes (AOP) and Electrochemical Oxidation: These methods can potentially degrade PFAS at the molecular level, but they are energy-intensive and still emerging technologies.

Carver Water often engineers integrated systems (e.g., GAC + RO + IX polishing) to balance cost, efficiency, and waste management.

Q5: Do you service systems not originally installed by Carver Water?

Yes. We service and optimize RO systems regardless of original manufacturer.

Q6: How big is the PFAS treatment market?

According to Bluefield Research, U.S. utilities will spend over $3 billion annually by 2030 on PFAS remediation technologies. Drivers include:

-Growing public health awareness.

-New state and federal mandates under the Safe Drinking Water Act.

-Federal grants funding PFAS technology pilots.

-Legal liabilities faced by manufacturers and utilities.

This makes PFAS the next major challenge for U.S. water utilities.

Q7: What are the biggest challenges with PFAS compliance?

Ultra-low regulatory limits (parts per trillion) require highly sensitive monitoring and treatment.

Short-chain PFAS removal remains technically difficult.

Disposal of PFAS waste (spent media, brine) is costly and environmentally sensitive.

High operational costs for advanced technologies like RO and AOP.

Uncertainty around future regulation—EPA is expected to expand its list of regulated PFAS compounds.

Carver Water’s role is to help utilities choose the right mix of technologies, secure funding, and manage ongoing compliance.

👉 Still have questions?

We're Here To Help!

Schedule a Tampa Reverse Osmosis Consultation

Talk directly with our engineering team about:

Tampa water quality challenges

Flow and purity requirements

Budget and timeline

Long-term maintenance planning

Innovation

Fresh, creative solutions.

Integrity

Honesty and transparency.

Excellence

Top-notch services.

FOLLOW US

TECHNOLOGY & SERVICES

ABOUT US

CUSTOMER CARE

LEGAL

Copyright 2026. Carver Water . All Rights Reserved.