PLC Fabrication

Introduction: Why Automation Matters in Water & Wastewater

Running a water or wastewater treatment facility isn’t just about moving water—it’s about safety, compliance, and efficiency. Behind the scenes, advanced automation keeps pumps, valves, chemical dosing, and monitoring systems running without interruption.

That’s where PLC Panel Fabrication comes in. At Carver Water, we specialize in designing, fabricating, programming, and installing custom PLC panels built specifically for the unique demands of the water and wastewater industry. Our panels ensure facilities operate smoothly, meet regulatory requirements, and reduce costly downtime.

What is PLC Panel Fabrication in Water Treatment?

PLC (Programmable Logic Controller) panel fabrication is the process of building the control hub that manages an entire water system. In simple terms, the PLC panel acts as the “brain” of pumps, blowers, filters, and chemical dosing equipment.

When Carver Water fabricates a PLC panel, we don’t just assemble parts—we engineer complete, turnkey automation solutions that integrate seamlessly with your existing plant operations.

Carver Water’s Process: From Drawings to Installation

At Carver Water, our approach to PLC Panel Fabrication follows a proven step-by-step method designed for reliability in the toughest environments.

Step 1: Engineering the Drawings

We begin with either:

Custom CAD designs tailored to your plant, or

Our standard designs developed from years of experience in water treatment.

These drawings serve as the blueprint, ensuring every wire, breaker, and relay has its place.

Step 2: Selecting the Enclosure

Next, we choose the right enclosure to protect the panel. For harsh water and wastewater environments, we typically recommend industrial-grade options such as a Hoffman Enclosure.

Why it matters: Enclosures keep out dust, moisture, and corrosion—critical in wet environments.

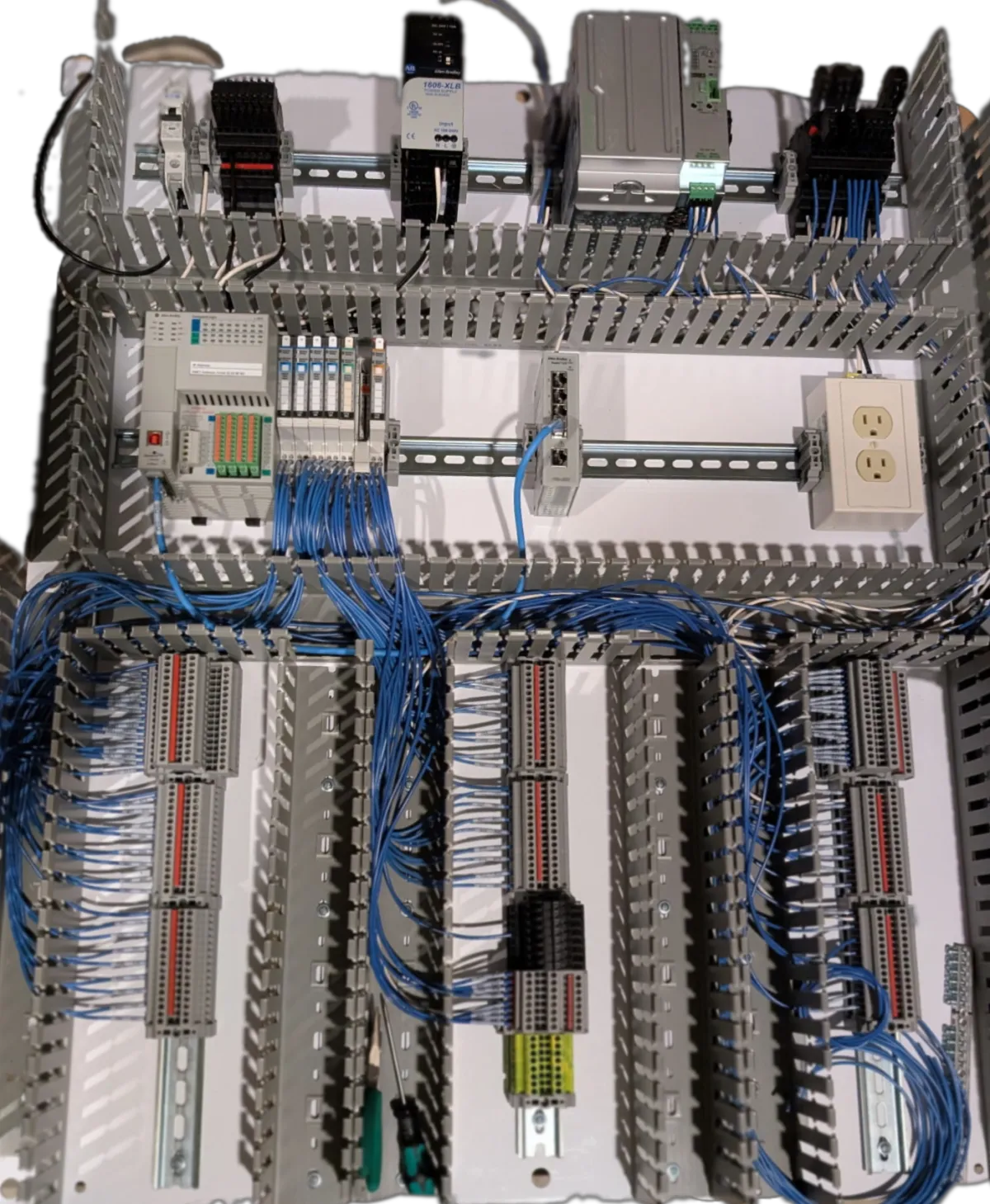

Step 3: Installing Components

Our skilled electrical and controls engineering team installs all PLC components with precision:

PLC units and power supplies

Input/output modules

Breakers, relays, and terminal blocks

Labeling for easy troubleshooting

Step 4: Programming the PLC

This is where the intelligence comes in. Our engineers program the PLC to:

Automate pump and blower operation

Monitor water quality sensors

Control chemical dosing systems

Trigger alarms for safety

Every program is tested and customized to your facility’s unique needs.

Step 5: Testing & Quality Assurance

Before leaving our shop, every panel undergoes rigorous testing:

Power and continuity checks

Simulation of field devices

Safety compliance verification

This ensures your panel arrives ready to perform from day one.

Step 6: Installation & Commissioning

Finally, our team installs and commissions the PLC panel onsite. We handle:

Mounting the enclosure

Connecting field devices (sensors, motors, valves)

Performing startup and operator training

At the end of the process, you have a fully operational, tested, and documented control system.

Why Water & Wastewater Facilities Trust Carver Water

Choosing Carver Water for PLC Panel Fabrication means you’re choosing:

✅ Industry Expertise – We specialize in water and wastewater automation.

✅ Turnkey Service – From design to installation, we handle everything.

✅ Compliance Assurance – Panels are designed to meet local, state, and federal regulations.

✅ Long-Term Reliability – Quality fabrication reduces downtime and maintenance.

Real Applications of Carver Water’s PLC Panels

Our panels are used across the water and wastewater industry, including:

Municipal Water Treatment Plants – Controlling pumps, filters, and chemical dosing.

Wastewater Treatment Facilities – Automating blowers, clarifiers, and sludge handling.

Industrial Water Systems – Managing process water for factories and food plants.

Best Practices We Follow

At Carver Water, we go beyond basic fabrication by implementing industry best practices:

Neat, labeled wiring for easy maintenance.

High-quality components from trusted manufacturers.

Ventilation and cooling to prevent overheating.

Scalable designs that allow for future plant upgrades.

Frequently Asked Questions — PLC Fabrication in Water Systems

1. What is PLC panel fabrication for water treatment systems?

PLC panel fabrication refers to designing and building custom control panels that house programmable logic controllers (PLCs) and associated components to automate and monitor water and wastewater equipment.

2. Why are PLCs important in water and wastewater treatment?

PLCs act as the control “brain” of treatment systems, automating pump operation, chemical dosing, sensor monitoring, alarms, and other functions critical for safety, compliance, and efficiency.

3. How does PLC automation improve plant performance?

Automating control logic reduces manual interventions, improves process consistency, enhances monitoring capability, and helps maintain regulatory standards efficiently.

4. What are the key steps in PLC panel fabrication?

The steps include engineering drawings, enclosure selection, component installation, programming logic, testing, and on-site commissioning.

5. Can PLC systems be integrated with SCADA or remote monitoring?

Yes. PLCs frequently integrate with SCADA systems or remote monitoring platforms to provide real-time analytics, data logging, alarms, and performance reporting.

6. Do PLC panels require ongoing maintenance?

Yes. PLC panels should be maintained with regular testing, firmware updates, backups, and inspections to ensure reliability and minimize downtime.

If you’re managing a water or wastewater facility, don’t settle for off-the-shelf solutions. Carver Water delivers custom PLC panel fabrication, programming, and installation tailored to your system’s needs.

👉 Schedule a consultation today and let us help you streamline your plant with reliable automation.